Top Things To Know About Different Types Of Lasers And How They Function

There are many different types of lasers on the market today, each with unique characteristics. This blog post will discuss some of the most common types of lasers and how they function. It will also provide information on what applications each laser is best suited for. So, if you’re curious about lasers and want to learn more about them, read on.

Semiconductor lasers

One of the most common types of lasers is the semiconductor laser. These lasers are made from materials like gallium arsenide and are used in various applications, such as CD and DVD players, fiber-optic communications, and laser pointers. These are also referred to as Laser Diodes because they use a diode to generate light. Semiconductor lasers are typically tiny and can be powered by a low-voltage power source, making them ideal for many portable devices. Semiconductor lasers are also relatively inexpensive to produce and are very reliable.

One drawback of semiconductor lasers is their relatively low output power. This means that they are not well suited for applications where high-power lasers are required, such as in medical procedures or industrial cutting and welding. They are also often used with other lasers to create a more powerful beam, so you must be careful when working with them. Semiconductor lasers are an excellent choice for many applications, but you must be aware of their limitations.

-

Solid-state lasers

Solid-state lasers are similar to semiconductor lasers but use a solid material, such as neodymium-doped glass or plastic, as their active medium. The active medium is what amplifies the light, making it more intense. They use a pump to excite the atoms in the active medium, emitting light. In this case, plastic or glass is used as the host material, and neodymium is used as the dopant. The host material gives the laser its properties, such as its wavelength, and the dopant gives it its color.

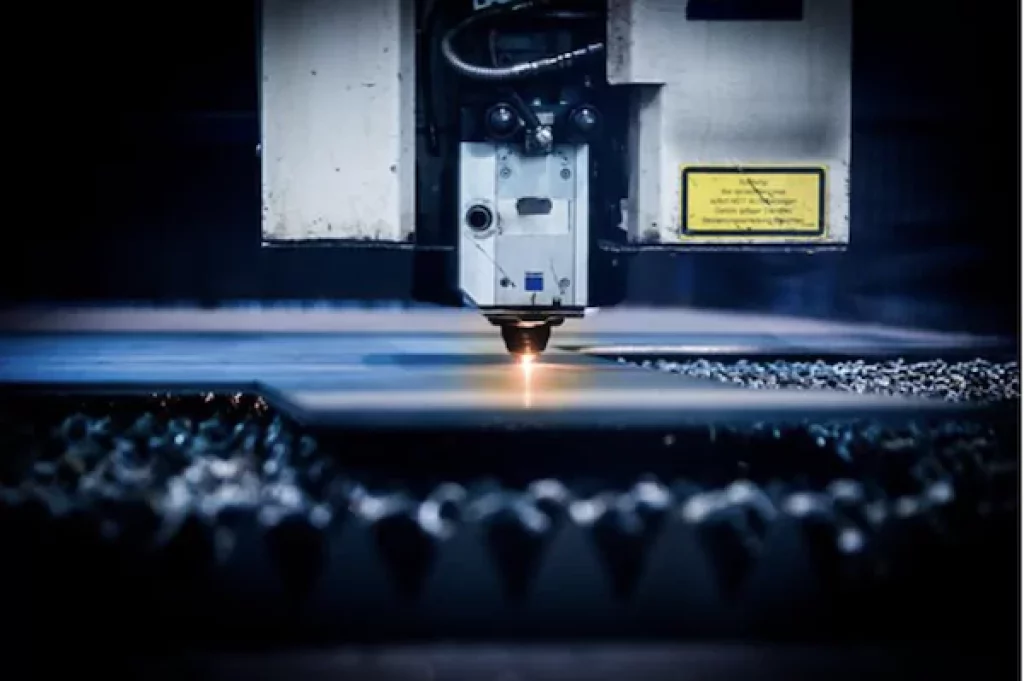

Solid-state lasers are typically potent and can be used for laser cutting and welding applications. When used in laser cutting, solid-state lasers can cut through materials much thicker than a semiconductor laser can handle. This is because the output power of a solid-state laser is much higher than that of a semiconductor laser. Another advantage of solid-state lasers is that they are very efficient and have a long lifetime. However, they are also more expensive and are not as common as other lasers.

Fiber lasers

You may also come across fiber lasers, a type of solid-state laser. These lasers use glass or plastic fiber as their active medium. Glass fiber is used more often than plastic because it can be made very pure, which results in a higher-quality beam. However, some take advantage of plastic because it is cheaper. In any case, the fiber transmits the light generated by the laser and amplifies it. This results in a concentrated beam that can be used for many different purposes.

Fiber lasers are typically used for applications requiring high precision, such as in medical procedures or cutting thin materials. In medical procedures, fiber lasers can be used to cut through tissue without damaging the surrounding area. This is because the beam can be focused into a tiny spot, allowing precise cuts. Fiber lasers can also produce clean and straight cuts when cutting thin materials. However, they are more expensive than other types of lasers because of the costly fiber used.

Liquid lasers

Sometimes referred to as dye lasers, liquid lasers use a liquid as their active medium. The most common type of liquid laser is the dye laser, which uses a solution of organic dye in water or another solvent. The organic dye is what amplifies the light, making it more intense. The dye is also responsible for the color of the laser beam. Dye lasers are typically used for applications where a wide range of colors is required, such as spectroscopy or holography.

Liquid lasers are not as standard as other types because they are less stable and have a shorter lifetime. However, they are still used in some applications because of their unique properties. For example, dye lasers can be tuned to produce particular colors, which is helpful in spectroscopy. Holography is another application where dye lasers are used because they can create high-quality images.

Gas lasers

Another type of laser is the gas laser. These lasers use a gas, such as carbon dioxide, nitrogen, or helium, as their active medium. Carbon dioxide lasers are the most common type of gas laser. They work by using an electric current to excite the atoms in the gas, which then emit light. The active medium amplifies the light, making it more intense. Nitrogen and helium lasers work similarly, but they use different gasses. Gas lasers are much larger than semiconductor lasers and require a higher-voltage power source to operate.

Gas lasers are typically used for industrial applications because they are compelling. For example, carbon dioxide lasers are often used for cutting and welding because they can cut through very thick materials. They are also used in engraving and etching because they can create exact designs. Nitrogen and helium lasers are also used for industrial applications but are not as common as carbon dioxide lasers. Just keep in mind that gas lasers are more expensive than other lasers and require more maintenance.

-

Excimer lasers

Excimer lasers are gas lasers that use a mixture of rare gasses, such as argon and krypton, as their active medium. Argon-krypton lasers are the most common type of excimer laser. These lasers work by using an electric current to create a plasma, which is then used to Excite the atoms in the gas. The light emitted by the excited atoms is then amplified by the active medium, making it more intense.

Now that you know a little bit more about the different types of lasers and how they function, you can decide which type of laser is best suited for your needs. A gas laser may be the best option if you need a powerful laser for industrial applications. However, a semiconductor laser may be the better choice if you need a less expensive and more portable one. Whatever your needs, there is sure to be a laser that can meet them.